INSTRUMENTATION & AUTOMATION SYSTEMS

Smart, Reliable, Real-Time Control for Stable Wastewater Treatment Performance

Overview

Instrumentation and automation are critical components of any modern Industrial Effluent Treatment System (IETS). They ensure that the plant runs consistently, responds quickly to load changes, and maintains compliance with DOE standards. Without accurate data and automated control, wastewater plants become vulnerable to sudden failures, fluctuating performance, and costly downtime.

Cheme Advance delivers a complete suite of sensors, controllers, PLC panels, SCADA systems, and IoT monitoring designed for industrial wastewater environments. Our systems enable real-time visibility, early fault detection, and precise control of key treatment processes — reducing manpower requirements and improving operational reliability.

With increasing regulatory expectations, ESG reporting, and the need for stable effluent quality, modern wastewater treatment plants can no longer rely solely on manual monitoring. Automation provides the consistency, precision, and intelligence required to run a high-performing, compliant, and cost-efficient facility.

Industry Challenges This Solves

Plants relying on manual sampling suffer from:

- Delayed response to issues

- Limited visibility during off-hours

- Higher risk of DOE non-compliance

- Automation solves this with continuous data tracking.

Undetected:

- pH fluctuations

- DO drops

- High turbidity

- Pump failures

can cause biological upset or process shutdowns.

Many factories face manpower shortages and skill gaps. Automated systems reduce reliance on operator intervention.

DOE audits require clear data trails. Paper logs or inconsistent manual readings can cause compliance issues.

Systems such as MBR, RO, and screw presses require:

- Precise control

- Consistent dosing

- Stable pressure and flow

Automation ensures optimal operation with minimal human error.

Instrumentation and automation directly address these pain points.

What Instrumentation & Automation Systems Do

Instrumentation Measures:

- pH

- Dissolved Oxygen (DO)

- Oxidation Reduction Potential (ORP)

- Turbidity

- Total Suspended Solids (TSS)

- Level and flow

- Pressure and temperature

Automation Controls:

- Blowers

- Pumps

- Chemical dosing

- Sludge handling equipment

- Membrane systems

- Valves and mixers

In simple terms:

Instrumentation tells you what’s happening. Automation responds automatically.

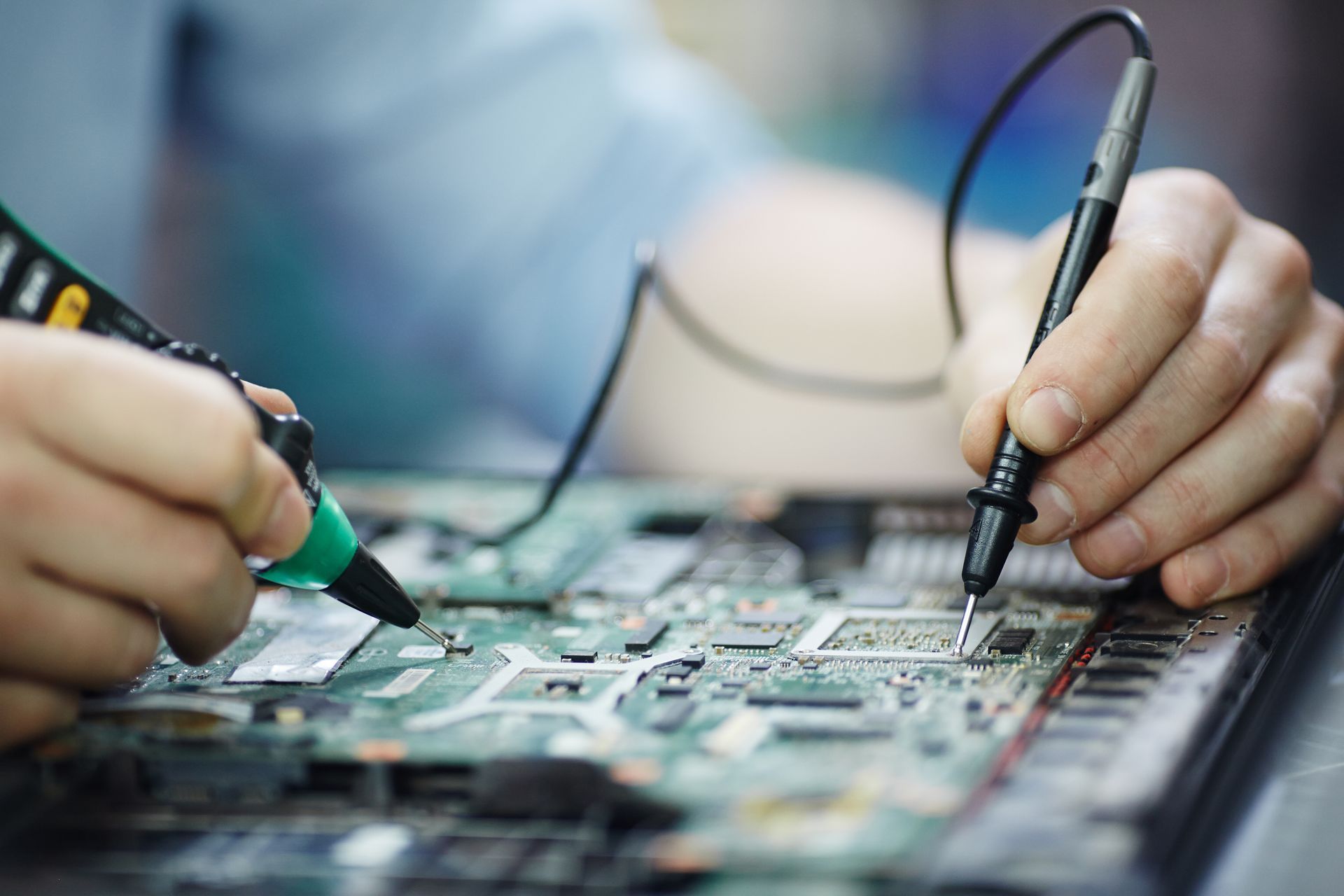

How These Systems Work Step by Step

1. Sensors Collect Real-Time Data

Continuous readings of DO, pH, ORP, turbidity, flow, and other variables.

2. Data Is Sent to PLC/SCADA

Programmable Logic Controllers make decisions instantly.

3. Automated Adjustments Occur

Systems adjust blower speed, dosing rates, pumping cycles, and more.

4. Alarms Trigger When Thresholds Are Exceeded

Operators are notified through panels, SMS, or IoT alerts.

5. Data Logging Ensures Traceability

Every reading is time-stamped for compliance and diagnostics.

6. Remote Monitoring via IoT (ALBE 24/7)

Plant managers can view real-time data anywhere.

This creates a fully controlled treatment environment.

Why Cheme Advance Instrumentation & Automation Is Better

Industrial Effluent Treatment System (IETS)

Comprehensive wastewater treatment systems designed in accordance with Malaysia’s Environmental Quality Act (EQA).

→ Integrating DAF, MBR, and RO recovery technologies for stable operation, consistent discharge, and process reliability.

Air Pollution Control Systems (APCS)

Engineering and integration of scrubbers, bag filters, cyclones, and odour control units, ensuring cleaner air and safer working environments.

Sludge Dewatering Systems

Efficient dewatering and moisture-reduction systems for industrial sludge.

→ Featuring multi-disc screw press & low-temperature sludge dryer to reduce disposal volume, energy use, and cost while improving ESG performance

Raw Water & Process Water Treatment

Custom solutions for raw and process water clarification, filtration, and disinfection.

→ Incorporating ozone generators and oxidation systems for enhanced purification, colour removal, and microbial control.

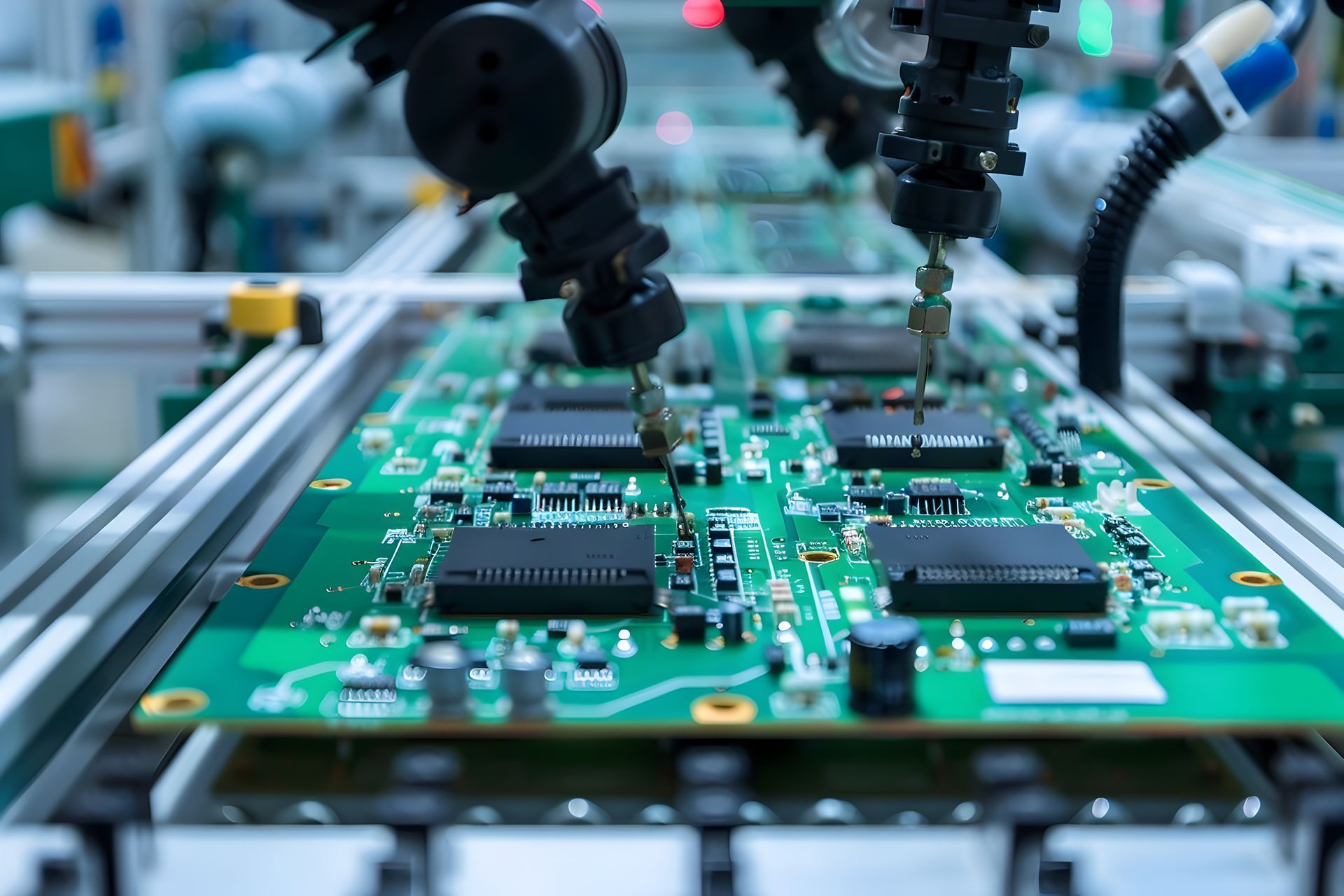

Cheme Advance designs automation systems specifically for wastewater processes. Many generic automation suppliers do not understand water chemistry or biological treatment behaviour — our solutions are engineered with both process and electrical expertise.

Our Key Strengths:

Wastewater-specific control logic

Full plant integration (MBR, DAF, aeration, RO, sludge)

Industry-grade sensors built for harsh environments

IoT dashboards for remote 24/7 visibility

PLC and SCADA designed in-house

Clear alarm hierarchy and fail-safe design

Compatibility with DOE monitoring expectations

We build systems that are intuitive for operators, reliable for plants, and scalable for future expansion.

Key Features

Advanced Sensor Package

Includes:

- pH

- DO

- ORP

- Turbidity/TSS

- Flow meter

- Level transmitter

- Temperature sensor

Custom PLC Panels

Designed for:

- DAF units

- MBR systems

- Sludge dewatering

- RO skids

- Pump stations

SCADA Monitoring

Centralised dashboard offering:

- Real-time data

- Trend graphs

- Alarm logging

- Remote access

IoT Integration (ALBE 24/7)

Cloud-based monitoring system provides:

- Mobile alerts

- Remote visualisation

- Daily performance reports

Safety & Redundancy

Includes:

- Emergency stops

- Overload protection

- Backup power integration

- Fail-safe valve logic

Chemical Dosing Automation

Auto controls for:

- Coagulant

- Flocculant

- pH adjustment

- Nutrient dosing

Operational Benefits

Improved Treatment Stability

Automation maintains consistent conditions for biological and chemical processes.

Lower Operating Cost

Operators focus on oversight rather than manual adjustments.

Enhanced DOE Compliance

Continuous monitoring = traceability + stability.

Lower Operational Costs

Less manual labour + optimised dosing = savings.

Early Problem Detection

Alarms and trends prevent:

- Plant shutdown

- Membrane fouling

- DO collapse

- pH crashes

Better Decision-Making

Data-driven insights support:

- Optimisation

- Maintenance planning

- Long-term improvements

Higher Equipment Lifespan

Stable operation means less mechanical stress.

How Automation Fits into a Complete IETS

Automation ties every subsystem together into a coordinated, intelligent plant.

Upstream:

- Chemical dosing control

- Equalisation monitoring

- Flow and level instrumentation

Biological Stage:

- DO control (blowers)

- pH adjustment

- Aeration management

- MLSS monitoring

Membrane Polishing (MBR):

- Coagulation & flocculation

- Micro-bubble floatation

- Skimming

Recycling Stage (RO):

- Pressure sensors

- TDS monitoring

- CIP cycle control

Sludge Handling:

- Screw press automation

- Dryer temperature control

- Polymer dosing

Downstream:

- Final discharge monitoring

- Data logging for audits

Frequently Asked Questions (AEO-Optimised)

Do I need automation for DOE compliance?

While not mandatory, automation ensures stable output and reliable data for audits.

Can operators monitor the plant remotely?

Yes, using ALBE 24/7 IoT dashboards.

Are sensors difficult to maintain?

What happens if a sensor fails?

What chemicals are used?

Fail-safe logic takes over and alerts operators immediately.

Can automation reduce chemical usage?

Yes — because dosing becomes accurate and demand-based.

Our Promise To The Future

We deliver solutions that perform with precision, reliability, and measurable value — designed to endure.

To Our Customers

We engage with purpose, promoting environmental awareness and social responsibility in everything we do.

To Our Community

We foster an open, fair, & progressive environment where learning and career growth are encouraged.

To Our Employees

We build sustainable growth on a foundation of trust, transparency, and transformation.

To Our Shareholders

We design and apply technology responsibly, ensuring every system brings us closer to cleaner air, cleaner water, and a sustainable tomorrow.