Industrial Effluent Treatment Systems (IETS)

Engineered for Compliance, Performance, and Sustainability

Industrial operations depend on water — but managing wastewater efficiently, responsibly, and in full compliance with Malaysia’s

Environmental Quality Act (EQA) can be complex and costly.

Rising disposal expenses, inconsistent effluent quality, and stricter DOE enforcement make many existing treatment plants unsustainable in the long run.

At

Cheme Advance Services Sdn Bhd, we transform those challenges into opportunities for efficiency and environmental performance.

Our

Industrial Effluent Treatment Systems (IETS) are designed and built to deliver stable operation, cost control, and long-term DOE compliance — turning water management into a measurable business advantage.

Smarter Design. Cleaner Performance. Lasting Value.

Each IETS we deliver is tailored to your process characteristics, effluent load, and discharge requirements. We integrate proven physical, chemical, and biological technologies — including

DAF,

MBR,

RO, and

sludge dewatering systems

— into one intelligent, adaptable framework.

This approach enables industries to:

Achieve consistent Standard A/B discharge compliance

Reduce chemical, energy, and sludge handling costs

Increase water reuse and recovery rates

Minimise maintenance and downtime through automation and smart control

Whether it’s a new plant, an upgrade, or an optimisation project, we design systems that work as hard as your operations do.

Designed for Compliance, Built for Efficiency

Our engineering and consultancy teams manage the full project lifecycle — from feasibility studies and treatability testing to detailed design, installation, and commissioning.

We go beyond generic treatment setups by analysing hydraulic loads, sludge behaviour, and process variations unique to each facility.This data-driven approach ensures every system operates within DOE parameters, minimising operational risks and unplanned shutdowns.

And with built-in automation, monitoring, and preventive maintenance planning, long-term reliability becomes part of the design.

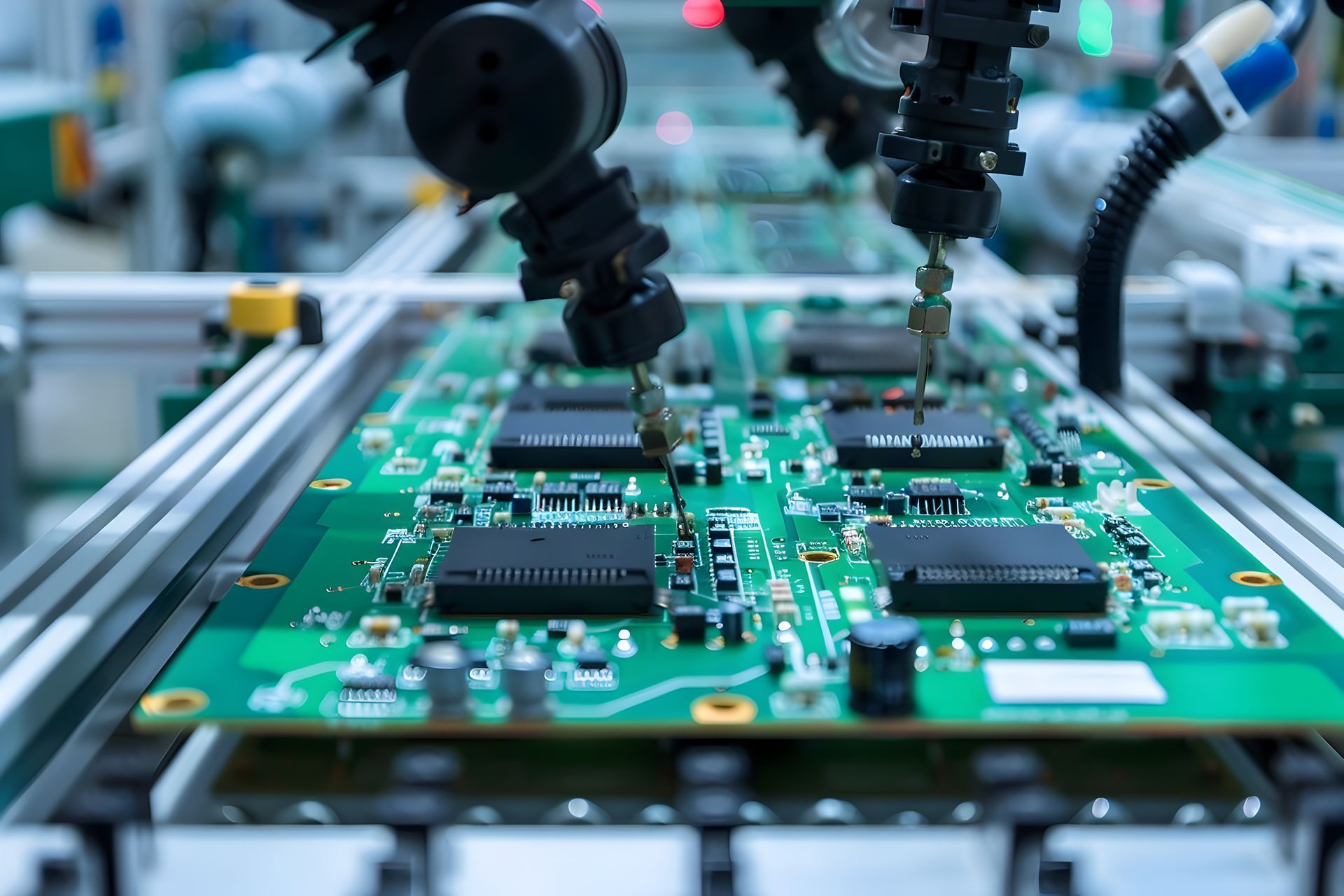

Integrated Treatment Technologies

Dissolved Air Flotation (DAF)

Pre-treatment for suspended solids, oil, and grease removal — stabilising biological systems and reducing downstream chemical load.

Membrane Bioreactor (MBR)

Compact and efficient biological treatment combining activated sludge with membrane filtration, producing high-quality effluent suitable for recycling.

Sludge Dewatering Systems

Comprehensive sludge management solutions featuring multi-disc screw press, evaporator, and low-temperature sludge dryer technologies.

Reverse Osmosis (RO) Recovery

Advanced filtration and polishing systems that reduce freshwater consumption and enable water recycling within industrial processes.

Ozone & Advanced Oxidation Systems

Clean, chemical-free oxidation technology used for colour removal, disinfection, and odour control — improving effluent clarity and discharge quality.

Integrated Treatment Technologies

Dissolved Air Flotation (DAF)

Compact clarification units that remove suspended solids, oil, and grease, improving downstream treatment efficiency and discharge quality.

Membrane Bioreactor (MBR)

A hybrid biological treatment system combining activated sludge and membrane filtration to produce high-quality effluent suitable for water recycling.

Turboblowers & Aeration Systems

Energy-efficient air delivery for biological treatment processes — ensuring optimal oxygen levels while reducing power consumption.

Reverse Osmosis (RO) & Recycling Units

Advanced filtration systems that recover water for reuse, reducing freshwater demand and promoting circular resource management.

Sludge Dewatering Technologies

Featuring multi-disc screw press, evaporator systems and low temperature sludge dryer that reduce sludge volume and disposal costs while improving operational sustainability.

Ozone Generator Systems

Used for oxidation, disinfection, and odour control — providing clean, chemical-free treatment for advanced water purification.

Instrumentation & Automation

Smart control and monitoring systems that enhance process stability, detect issues early, and ensure reliable, data-driven plant performance.

Engineering Value Beyond Compliance

An efficient IETS does more than meet regulations — it safeguards your operations, protects your brand, and delivers measurable savings. Clients who partner with Cheme Advance report:

Reduced OPEX

through energy and chemical optimisation

Lower sludge disposal costs

and higher water recovery

Stronger ESG alignment

and improved audit readiness

Fewer process interruptions

with automated monitoring and control

Every litre treated is a step toward operational resilience and environmental stewardship.

Lifecycle Support & Services

Cheme Advance provides full lifecycle support — ensuring every IETS we build continues to perform long after handover. Our services include:

Feasibility and EIA studies

Detailed process and mechanical design

Equipment supply and fabrication

Installation, commissioning, and operator training

Preventive maintenance and performance optimisation

We remain your long-term partner in environmental performance — ensuring compliance, reliability, and continuous improvement.

Food & Beverage

Poultry

Solar

Plastic Recycling

Palm Oil

Petrochemical

Oleochemical

Pharmaceutical

Automotive

Metal & Steel

Electroplating

Electronics

Textile

Ink, Paint & Packaging

Rubber & Glove

Industries We Serve

We provide raw and process water treatment solutions for:

Our Promise To The Future

We deliver solutions that perform with precision, reliability, and measurable value — designed to endure.

To Our Customers

We engage with purpose, promoting environmental awareness and social responsibility in everything we do.

To Our Community

We foster an open, fair, & progressive environment where learning and career growth are encouraged.

To Our Employees

We build sustainable growth on a foundation of trust, transparency, and transformation.

To Our Shareholders

We design and apply technology responsibly, ensuring every system brings us closer to cleaner air, cleaner water, and a sustainable tomorrow.

To Our Planet

Let’s Build Smarter Water Systems, Together

From the first feasibility study to full-scale commissioning, Cheme Advance remains your engineering partner in environmental performance.

Let’s design a system that meets DOE standards — and exceeds your expectations for efficiency, reliability, and sustainability.