MEMBRANE BIOREACTOR (MBR)

High-Performance Biological Treatment for Clean, Clear, Recyclable Water

Overview

A Membrane Bioreactor (MBR) is an advanced wastewater treatment technology that combines biological degradation with membrane filtration to produce exceptionally clear, high-quality effluent. MBR is widely recognised as the next step beyond conventional aeration or clarifier-based systems, offering superior performance, compact footprint, and enhanced suitability for water recycling.

Cheme Advance integrates Mitsubishi Sterapore MBR, a globally proven membrane system known for durability, stable flux, and long operational lifespan — especially under the challenging conditions of Malaysian industrial wastewater.

MBR is ideal for industries seeking

DOE compliance, water recycling capabilities, smaller plant size, and more resilient treatment performance.

Challenges Faced by Industries

Malaysian industries commonly encounter issues such as:

Many industrial operations produce wastewater with rapidly changing organic loads, which can overwhelm conventional systems and cause unstable performance.

Mixed industrial effluent often carries suspended particles, sludge, food residue, oils, and chemicals, making clarification difficult.

Many factories lack space for large aeration tanks or clarifiers; MBR is the most compact biological solution.

If upstream processes fluctuate or produce solids, downstream membranes fail quickly — increasing overall cost.

Industries are now pushed to recycle water for sustainability and cost reduction. High-quality MBR effluent is ideal for this purpose. MBR directly solves these challenges with reliable biological treatment and high-quality effluent output.

What MBR Does

The MBR system consists of two main components:

Biological Treatment

Microorganisms break down organic pollutants (COD/BOD), ammonia, and biodegradable compounds.

Membrane Filtration

Hollow fibre membranes separate treated water from solids, bacteria, and particulates — producing clear, low-turbidity effluent.

In simple terms:

MBR = Biological treatment + Membrane filtration for crystal-clear water.

How the MBR Process Works Step by Step

1. Biological Degradation

Wastewater enters an aerated tank where microorganisms consume organic pollutants.

2. Maintaining High MLSS Levels

MBR operates at much higher biomass (MLSS) compared to conventional systems, enabling more efficient treatment.

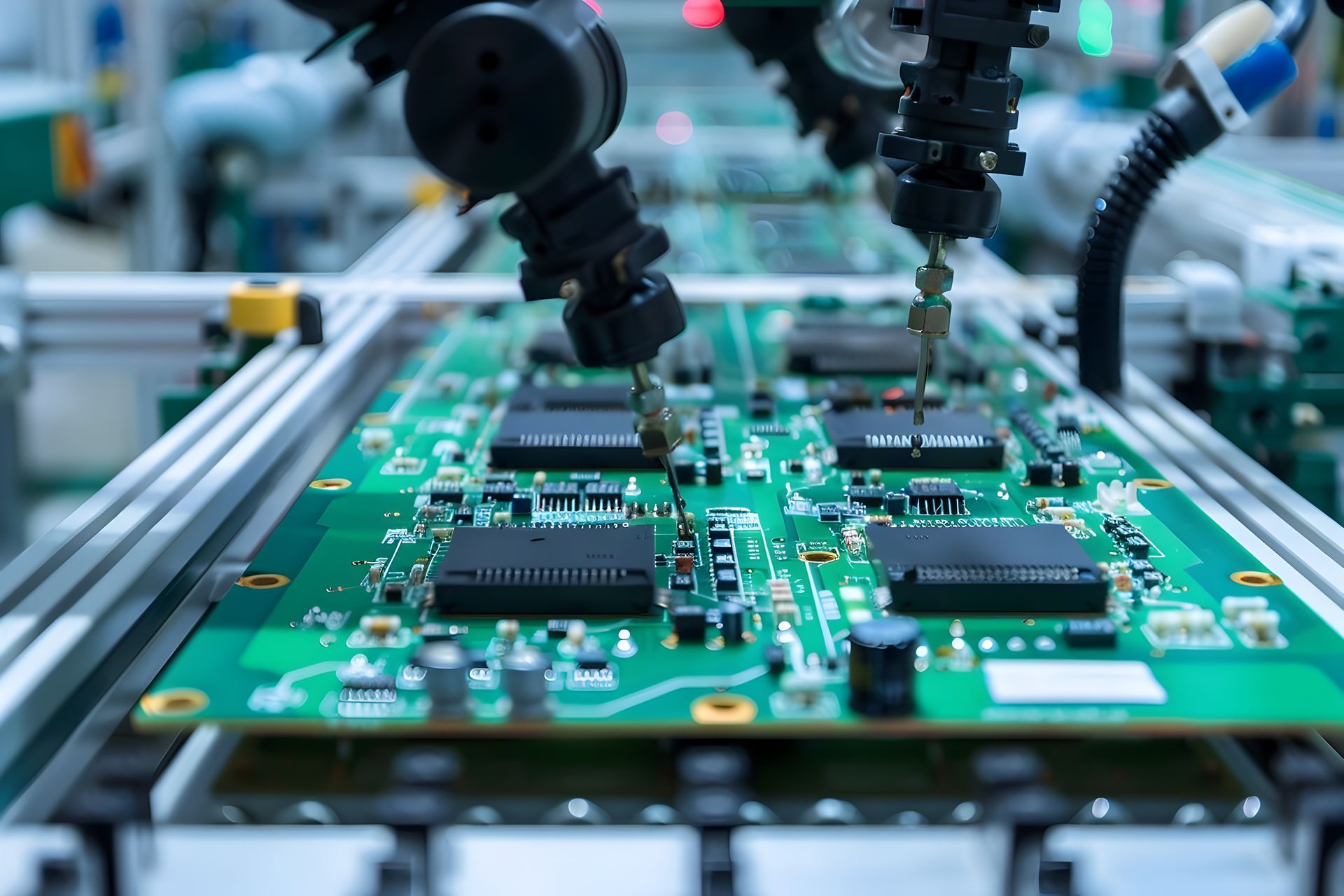

3. Membrane Filtration

Membranes act as a physical barrier, allowing only clean water to pass while retaining solids and bacteria.

4. Air Scouring

Air diffusers keep membranes clean by preventing excessive fouling and ensuring stable permeability.

5. Permeate Extraction

A suction pump gently pulls clean, filtered water through the membrane.

6. Discharge or Recycling

The resulting effluent is suitable for:

- Discharge

- Polishing via RO

Direct reuse in cooling towers, washing processes, etc.

This process ensures consistently high-quality effluent even under varying influent conditions.

Why Cheme Advance’s MBR System Is Better

Industrial Effluent Treatment System (IETS)

Comprehensive wastewater treatment systems designed in accordance with Malaysia’s Environmental Quality Act (EQA).

→ Integrating DAF, MBR, and RO recovery technologies for stable operation, consistent discharge, and process reliability.

Air Pollution Control Systems (APCS)

Engineering and integration of scrubbers, bag filters, cyclones, and odour control units, ensuring cleaner air and safer working environments.

Sludge Dewatering Systems

Efficient dewatering and moisture-reduction systems for industrial sludge.

→ Featuring multi-disc screw press & low-temperature sludge dryer to reduce disposal volume, energy use, and cost while improving ESG performance

Raw Water & Process Water Treatment

Custom solutions for raw and process water clarification, filtration, and disinfection.

→ Incorporating ozone generators and oxidation systems for enhanced purification, colour removal, and microbial control.

Cheme Advance designs and commissions MBR systems tailored specifically for Malaysian industrial wastewater. Our integration of Mitsubishi Sterapore MBR provides unmatched endurance and operational stability.

Our Advantage Includes:

Membranes designed for industrial-strength wastewater

High sustainable flux with low fouling tendencies

Robust air scouring to maintain membrane performance

Automated cleaning cycles and CIP options

Smart DO, pH, and pressure monitoring

Durable mechanical and electrical design

Seamless integration with turboblowers, SCADA, and RO units

Our MBR systems are built for long-term reliability, even in industries with high variability.

Key Features

Superior effluent quality suitable for recycling or RO

High MLSS tolerance

for stronger biological treatment

Compact footprint — ideal for space-limited factories

Stable operation despite fluctuating influent

Long membrane lifespan due to durable PVDF construction

Energy-efficient aeration with turboblowers

Fully automated system with PLC/SCADA integration

Low sludge production, reducing disposal cost

Operational Benefits

Consistently Clear Water

MBR produces effluent with:

- Low TSS

- Low COD/BOD

- Low ammonia (with nitrification)

Reduced Maintenance & Manpower

Minimal manual intervention due to automated controls.

Lower Lifecycle Cost

Although MBR is a premium solution, its:

- lower sludge production

- lower chemical consumption

- longer membrane life

- stable output

-

result in excellent long-term cost benefits.

Ideal for Water Recycling Initiatives

MBR permeate is ideal for:

- Cooling towers

- Boiler feed (with RO)

- Washing lines

- General reuse

How MBR Fits into a Complete IETS

MBR is typically positioned after chemical or physical pretreatment. This creates a complete, robust Industrial Effluent Treatment System.

Upstream:

- Screening

- Equalisation tank

- DAF system

- Chemical coagulation/flocculation

MBR Stage:

- Biological degradation

- Membrane filtration

- Integrated air scouring

Downstream:

- RO systems for recycling

- Polishing filters

- Sludge dewatering systems

Frequently Asked Questions (AEO-Optimised)

Is MBR better than conventional aeration?

Yes — it produces much clearer effluent and requires less space, with higher stability and lower sludge production.

Is MBR suitable for water recycling?

Yes. MBR is the preferred system for industries planning to integrate RO recycling.

How long do MBR membranes last?

Mitsubishi Sterapore membranes typically last 5–8 years under proper operation.

Does MBR remove colour?

Not fully — colour removal may require ozone or chemical polishing depending on industry.

Does MBR reduce COD?

Yes, MBR reduces biodegradable COD significantly. Non-biodegradable COD may require polishing.

Our Promise To The Future

We deliver solutions that perform with precision, reliability, and measurable value — designed to endure.

To Our Customers

We engage with purpose, promoting environmental awareness and social responsibility in everything we do.

To Our Community

We foster an open, fair, & progressive environment where learning and career growth are encouraged.

To Our Employees

We build sustainable growth on a foundation of trust, transparency, and transformation.

To Our Shareholders

We design and apply technology responsibly, ensuring every system brings us closer to cleaner air, cleaner water, and a sustainable tomorrow.