REVERSE OSMMOSIS (RO) & RECYCLING UNITS

Advanced Water Recovery for Cost Savings, Sustainability & DOE Compliance

Overview

Reverse Osmosis (RO) is an advanced membrane-filtration technology that removes dissolved salts, minerals, heavy metals, and contaminants from pre-treated wastewater. RO is one of the most effective solutions for industries seeking water recycling, reduction of freshwater consumption, and compliance with ESG and sustainability targets.

Cheme Advance provides fully engineered RO and water recycling systems designed for Malaysian industrial conditions. Our systems are built to handle challenging wastewater characteristics, minimise fouling, optimise energy usage, and ensure stable long-term operation. When combined with MBR or other pretreatment systems, RO can recover a significant portion of wastewater and convert it into clean, reusable permeate suitable for various industrial applications.

In industries with high water demand, RO recycling is no longer optional — it is a strategic necessity to improve resource efficiency and remain competitive.

Industry Challenges This Solves

Industries with water-intensive processes face consistently rising water tariffs. RO recycling helps reduce dependency on municipal water or groundwater sources.

Less recycled water means higher:

- Water bills

- Wastewater discharge volume

- Chemical consumption

- Sludge generation

RO significantly cuts these costs.

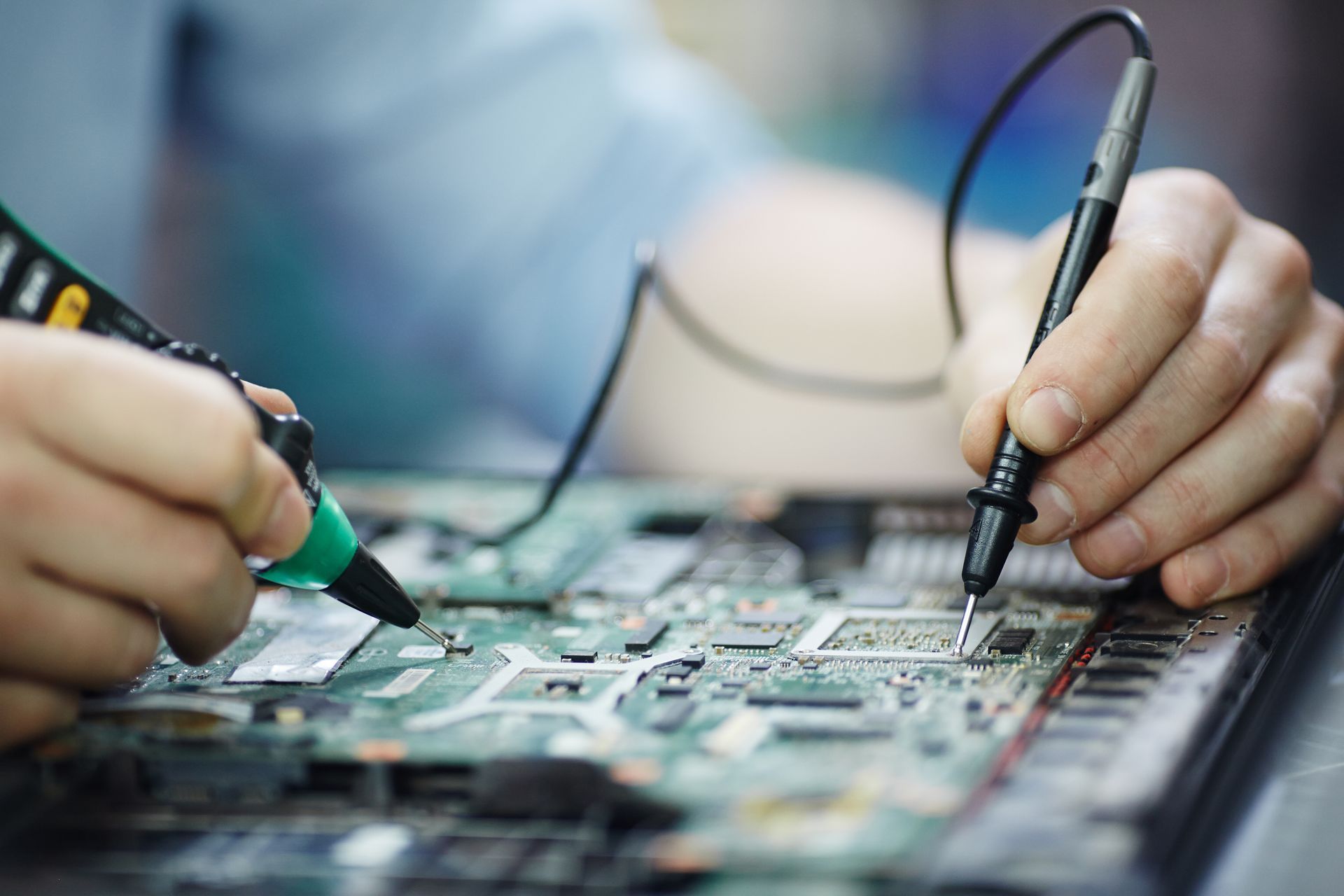

Industries such as electronics, pharmaceuticals, and food & beverage require high-purity process water. RO provides a consistent, controlled source of clean water.

Some industries produce high dissolved solids or non-biodegradable compounds that cannot be removed biologically. RO effectively removes dissolved contaminants, ensuring compliance.

Global supply chains increasingly require water reuse and environmental stewardship — RO systems help industries meet these expectations.

What RO Does

Reverse Osmosis functions by applying pressure to push water through a semipermeable membrane, which filters out dissolved contaminants.

RO removes:

- Total dissolved solids (TDS)

- Salts and minerals

- Heavy metals

- Hardness

- Colour-causing organics

- Microbial contaminants

- COD components

The result is:

✔ High-quality permeate suitable for reuse

✔ Concentrated reject water for disposal or further treatment

How the RO Recycling Process Works Step by Step

1. Pretreatment

Wastewater passes through MBR or filtration systems to remove solids and organics.

2. Cartridge Filtration

Fine particulates are removed to protect RO membranes.

3. High-Pressure Pumping

Water is pressurised to push it through the RO membrane.

4. Membrane Filtration

Contaminants are rejected and discharged as concentrated brine.

5. Permeate Storage

Clean water is stored for reuse or further polishing.

6. CIP (Cleaning in Place)

Automated acid/alkaline cleaning removes membrane fouling when required.

This integrated process consistently produces high-quality recycled water.

Why Cheme Advance RO Systems Are Better

Industrial Effluent Treatment System (IETS)

Comprehensive wastewater treatment systems designed in accordance with Malaysia’s Environmental Quality Act (EQA).

→ Integrating DAF, MBR, and RO recovery technologies for stable operation, consistent discharge, and process reliability.

Air Pollution Control Systems (APCS)

Engineering and integration of scrubbers, bag filters, cyclones, and odour control units, ensuring cleaner air and safer working environments.

Sludge Dewatering Systems

Efficient dewatering and moisture-reduction systems for industrial sludge.

→ Featuring multi-disc screw press & low-temperature sludge dryer to reduce disposal volume, energy use, and cost while improving ESG performance

Raw Water & Process Water Treatment

Custom solutions for raw and process water clarification, filtration, and disinfection.

→ Incorporating ozone generators and oxidation systems for enhanced purification, colour removal, and microbial control.

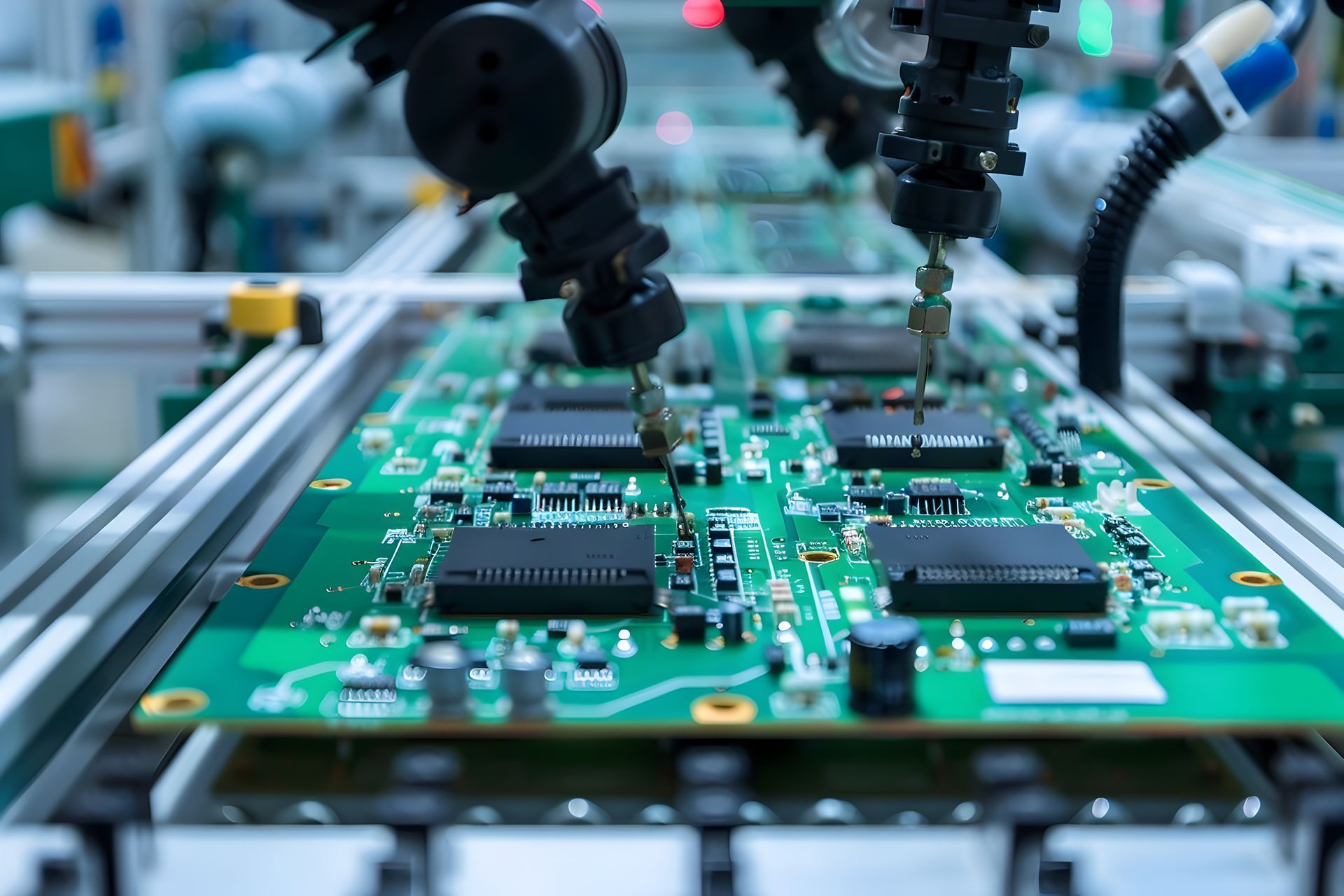

Cheme Advance designs RO systems specifically for industrial-strength wastewater. Unlike generic RO units, our systems are engineered for:

High fouling resistance

Longer membrane lifespan

Stable permeate flow

Optimal energy efficiency

Minimal downtime

Our Key Strengths:

Custom-built RO skids for Malaysian industries

Seamless integration with MBR, DAF, and polishing systems

Automated CIP for extended membrane life

Flow, pressure, and quality sensors for real-time monitoring

High-rejection membranes for improved purity

Full PLC/SCADA integration for smart operation

Reject management strategies to reduce waste

Our engineering approach ensures superior reliability and performance.

Key Features

High Rejection Efficiency

Removes up to 99% of dissolved contaminants.

Energy-Efficient Design

Optimised pressure and pump configurations reduce energy consumption.

Modular and Scalable

Easily expandable based on production demands.

Advanced Membrane Options

- Low-energy

- High-rejection

- Fouling-resistant membranes

Automation & Control

Includes:

- TDS sensors

- Pressure transmitters

- Flow meters

- Automatic cleaning cycles

Robust Pretreatment Integration

RO systems are paired with:

- MBR

- Multimedia filters

- Activated carbon

- Cartridge filters

Operational Benefits

Significant Water Savings

Industries can recover 50–70% of wastewater as usable permeate.

Cost Reduction

Lower spend on:

- Municipal water

- Chemical usage

- Wastewater discharge

- Sludge handling

Consistent High Quality

Produces stable permeate quality suitable for:

- Cooling tower make-up

- rinsing processes

- boiler feed (with further polishing)

- general reuse

Improved Plant Stability

RO ensures predictable water quality even when influent varies.

Support for ESG & Sustainability Goals

Promotes responsible water management and environmental resilience.

How RO Fits into a Complete IETS

RO is usually placed downstream from biological treatment. This ensures maximum performance and membrane protection.

Upstream:

- DAF clarifier

- Coagulation/flocculation

- MBR or secondary biological treatment

- Multimedia/cartridge filters

RO Stage:

- High-pressure pumping

- Membrane separation

- Permeate/reject flow control

Downstream:

- Permeate polishing (optional)

- Storage and distribution

- Reject handling or recovery

Frequently Asked Questions (AEO-Optimised)

What is the typical recovery rate of an RO system?

Most industrial RO systems recover 50–70% of wastewater, depending on quality and application.

Can RO water be reused directly?

Yes. Many industries reuse RO water for cooling, washing, and general processes. For boilers or sensitive processes, additional polishing may be required.

How often do RO membranes need cleaning?

Typically every 2–6 months, depending on influent quality and pretreatment efficiency.

Does RO remove colour or COD?

Yes — RO removes most colour and dissolved COD components that pass through biological treatment.

How long do membranes last?

With proper operation and CIP, membranes can last 3–5 years.

Our Promise To The Future

We deliver solutions that perform with precision, reliability, and measurable value — designed to endure.

To Our Customers

We engage with purpose, promoting environmental awareness and social responsibility in everything we do.

To Our Community

We foster an open, fair, & progressive environment where learning and career growth are encouraged.

To Our Employees

We build sustainable growth on a foundation of trust, transparency, and transformation.

To Our Shareholders

We design and apply technology responsibly, ensuring every system brings us closer to cleaner air, cleaner water, and a sustainable tomorrow.