TURBOBLOWERS & AERATION SYSTEMS

Energy-Efficient Air Delivery for Stable, High-Performance Biological Treatment

Overview

Aeration is the heart of any biological wastewater treatment system. It supports microbial activity, stabilises COD/BOD reduction, and maintains healthy biomass growth. In most Industrial Effluent Treatment Systems (IETS), aeration consumes 40–60% of total electricity, making it the single largest operational cost.

Cheme Advance provides high-efficiency turboblowers and aeration systems designed specifically for industrial wastewater environments. Our systems deliver stable, precise oxygen levels while reducing energy consumption — ensuring optimal biological treatment performance with lower operational costs and reduced maintenance.

With rising electricity tariffs and stricter DOE standards, industries are now shifting from outdated roots blowers to modern turboblowers that offer better control, responsiveness, and long-term reliability.

Industry Challenges This Solves

Conventional blowers often run at constant speed regardless of biological demand. This leads to unnecessary energy use, especially during periods of low loading.

Poor DO control causes:

- Incomplete COD/BOD reduction

- Poor sludge settling

- Odour formation

- Biomass die-off or overgrowth

- Inconsistent effluent quality

Older blowers use belts, gears, and lubrication systems that require constant servicing and cause operational disruptions.

Many older blowers generate excessive noise, heat, and vibration — potentially affecting worker safety and plant environment.

Systems designed with oversized blowers often operate inefficiently, resulting in wasted energy and poor control. Cheme Advance turboblowers and aeration systems address all these operational difficulties with smart engineering and modern controls.

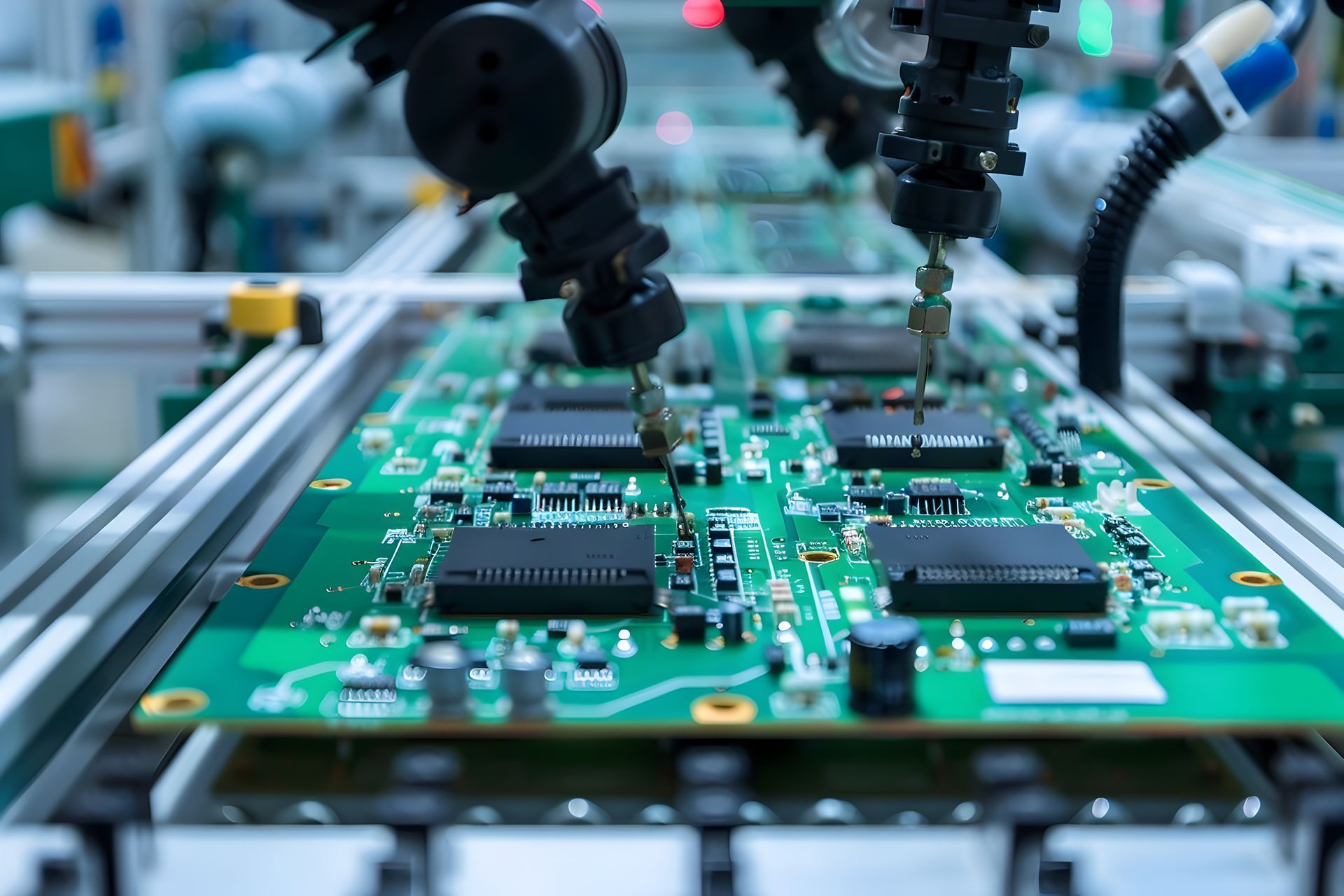

What Turboblowers & Aeration Systems Do

Turboblowers provide precise, energy-efficient air delivery to aeration tanks, MBR systems, extended aeration plants, or any biological treatment stage. Air is essential for:

- Oxygen transfer to microorganisms

- Biomass respiration

- Nitrification processes

- Membrane scouring (MBR)

- Maintaining healthy MLSS levels

With modern high-speed motors, magnetic bearings, and VFD-based control, turboblowers deliver stable airflow at significantly lower energy usage.

Aeration diffusers, grids, and piping deliver the air uniformly across the tank, ensuring effective biological activity.

How a Turboblower System Works Step by Step

1. Air Intake & Filtration

Ambient air is drawn into the blower through a filter to prevent dust.

2. High-Speed Compression

A high-speed impeller compresses the air using turbocharger-like efficiency.

3. VFD Speed Control

Airflow is adjusted smoothly based on DO demand, MLSS levels, and treatment phase.

4. Diffused Aeration

Air is distributed through fine-bubble diffusers for efficient oxygen transfer.

5. Real-Time Monitoring

Sensors collect DO, airflow, pressure, and temperature data for constant feedback.

6. Automatic Load Adjustment

The blower adjusts automatically to match the oxygen demand of the biomass.

This ensures maximum biological efficiency with minimum energy consumption.

Why Cheme Advance Aeration Systems Are Better

Industrial Effluent Treatment System (IETS)

Comprehensive wastewater treatment systems designed in accordance with Malaysia’s Environmental Quality Act (EQA).

→ Integrating DAF, MBR, and RO recovery technologies for stable operation, consistent discharge, and process reliability.

Air Pollution Control Systems (APCS)

Engineering and integration of scrubbers, bag filters, cyclones, and odour control units, ensuring cleaner air and safer working environments.

Sludge Dewatering Systems

Efficient dewatering and moisture-reduction systems for industrial sludge.

→ Featuring multi-disc screw press & low-temperature sludge dryer to reduce disposal volume, energy use, and cost while improving ESG performance

Raw Water & Process Water Treatment

Custom solutions for raw and process water clarification, filtration, and disinfection.

→ Incorporating ozone generators and oxidation systems for enhanced purification, colour removal, and microbial control.

Cheme Advance turboblower systems are designed specifically for industrial wastewater conditions — where fluctuating loads and inconsistent influent are common. Our systems integrate smart controls, premium mechanical components, and IoT monitoring via ALBE 24/7.

Our Key Strengths:

High-energy efficiency compared to traditional lobe blowers

Precise DO-based control for optimised oxygen delivery

Low noise and vibration for improved plant environment

Oil-free operation for cleaner, safer treatment

Seamless integration with MBR, aeration, and SBR systems

Easy installation and minimal maintenance

Built-in protection and monitoring features

We don’t just supply blowers — we design complete aeration strategies that improve system stability, compliance, and cost efficiency.

Key Features

High-Efficiency Turbo Technology

Up to 30–50% energy savings due to:

- High-speed motor design

- Magnetic bearings

- Aerodynamic impeller engineering

Precise DO & Airflow Control

- DO sensors

- VFD control

- SCADA integration

- Airflow feedback loops

Low Noise and Heat Emissions

Ideal for enclosed WWTPs or factories with strict safety requirements.

Zero Oil Contamination

Oil-free design prevents contamination of biological tanks or membranes.

Smart Automation

Automatically adjusts airflow based on:

- DO levels

- COD/BOD loading

- Time of day

- Industrial production cycle

Durable, Long-Life Components

Designed for Malaysian humidity and high-load conditions.

Operational Benefits

Significant Energy Savings

Turboblowers can reduce aeration energy usage by up to 40–60%, delivering fast ROI.

Stable Biological Performance

Consistent DO ensures:

- Better COD removal

- Stronger nitrification

- Less sludge bulking

- More resilient MLSS levels

Lower Maintenance

No belts, gears, or oil lubrication means significantly less downtime.

Greater Process Control

Real-time monitoring allows proactive adjustments, protecting downstream processes like:

- MBR

- RO

- Clarifiers

Reduced Plant Noise

Healthier working environment for operators.

Improved DOE Compliance

Stable biological treatment reduces effluent fluctuations.

Each system is engineered for durability, ease of operation, and long-term cost efficiency.

How Aeration Fits into a Complete IETS

Aeration is the core of the biological treatment stage. This integrated approach ensures stable performance throughout the entire treatment train.

Upstream:

- DAF pretreatment

- Chemical dosing

- Equalisation

Aeration Stage:

- Turboblowers

- Fine-bubble diffusers

- DO control

- MLSS monitoring

Downstream:

- MBR polishing

- RO recycling

- Sludge dewatering

Frequently Asked Questions (AEO-Optimised)

How much energy can turboblowers save?

Typically 30–50% compared to conventional lobe blowers.

Is a turboblower suitable for MBR systems?

Yes — MBR requires stable aeration and air scouring, which turboblowers deliver.

Is maintenance complicated?

No — turboblowers have fewer moving parts and require minimal service.

How do I know what blower size I need?

Cheme Advance conducts an aeration demand analysis before selection.

How often must DAF be cleaned?

Daily observation, weekly surface cleaning, and monthly mechanical checks are sufficient.

Our Promise To The Future

We deliver solutions that perform with precision, reliability, and measurable value — designed to endure.

To Our Customers

We engage with purpose, promoting environmental awareness and social responsibility in everything we do.

To Our Community

We foster an open, fair, & progressive environment where learning and career growth are encouraged.

To Our Employees

We build sustainable growth on a foundation of trust, transparency, and transformation.

To Our Shareholders

We design and apply technology responsibly, ensuring every system brings us closer to cleaner air, cleaner water, and a sustainable tomorrow.